Heat-affected Zone: All Aspects of HAZ That We Should Know

Due to its outstanding strength and durability, TMT (Thermo-Mechanically Treated) bar is a commonly utilized material in the construction industry. The Heat Affected Zone (HAZ) forms around the surface of the bar exposed to high temperatures during the butt jointing procedure when two bars are linked together to produce a continuous length. The integrity of the TMT bar in butt joints we examine the HAZ phenomena and talk about how to mitigate its consequences.

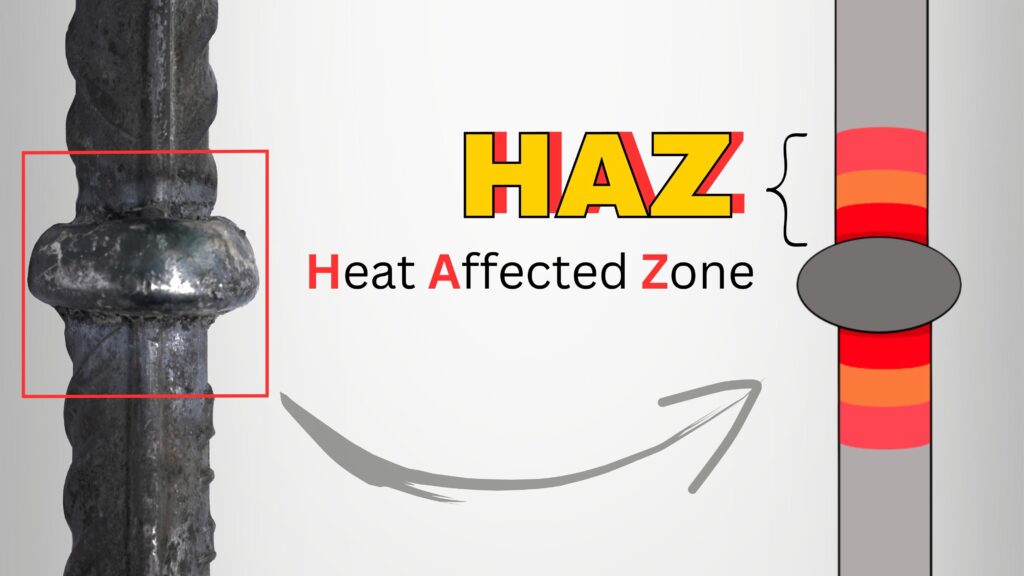

- When performing a Butt Joint, a substantial amount of heat is generated due to the high electric current used in the process. The intense heating and rapid cooling can cause changes in the microstructure of the TMT bar, leading to the formation of the Heat Affected Zone (HAZ). The size of the HAZ can vary depending on several factors, including cooling rate, temperature, material composition, and heat exposure duration. Its typical range of HAZ is 5-10mm from the joint interface.

- Heat-Affected Zone is a region of the TMT bar that has been altered by the heat generated during the butt joint. The HAZ can significantly impact the properties of the joint, particularly the Strength and Ductility.

- The high electric current used in the butt joint induces significant heat. That excess heat will change in microstructure and form undesirable properties.

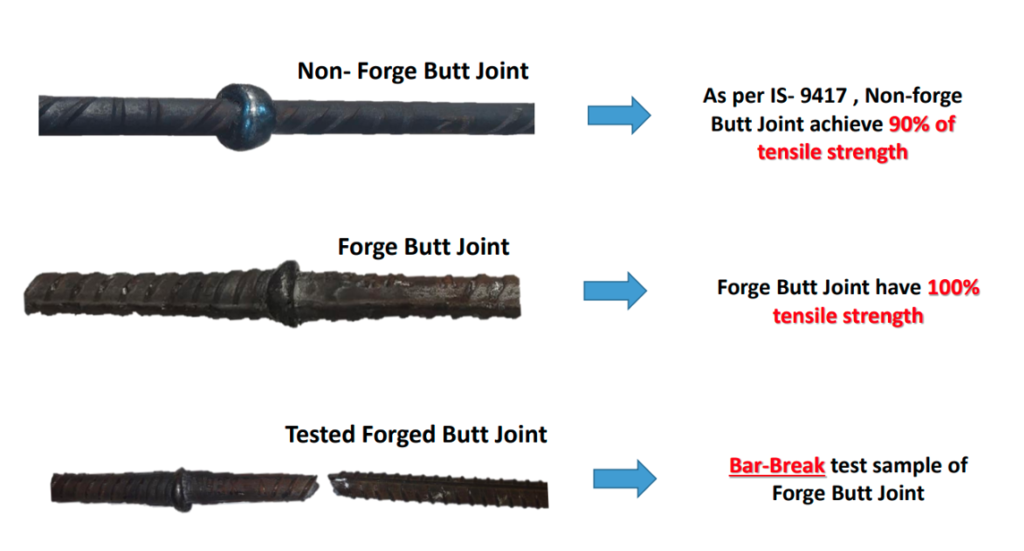

Note: No doubt HAZ is an important parameter in the Butt Joint however the butt joint strength of the TMT bar has reached up to 90% tensile strength of the steel bar that is accepted by IS 9417:2018. But if we want to increase joint strength above 90%, we have to Cold Forge the TMT bar before execution of the Butt joint.

BUTT JOINT

Conclusion:

When butt-joining TMT bars, the Heat Affected Zone (HAZ) is an important factor to take into account. The quality and durability of the joint may be protected, maintaining the structural integrity of building projects, with the right knowledge and management of the HAZ. We can successfully counteract the impacts of HAZ and enhance the Butt Joint strength by the use of the Cold Forge Technique.