Safety & Integrity of Structure: A Concern of Structure Consultant

As a structural engineer, crucial factors to consider in Butt joints regarding the Heat Affected Zone (HAZ) and TMT rebar properties include the butt joint process’s potential impact on TMT rebars’ high strength and ductility. Special attention is required to assess microstructural alterations, potential strength reduction, and residual stresses. Collaborative efforts with welders and quality control teams are essential to ensure joint quality and implement post-joint heat treatment if necessary, guaranteeing the structural integrity and safety of the construction project.

Is HAZ affect TMT rebar properties?

The structural engineer did, however, express worry about the heat-affected zone (HAZ) connected to Butt Joint. The HAZ is the region of the metal next to the joint where the butt joint process’ application of heat has changed the metal’s microstructure. The material qualities may change as a result of this modification, potentially impacting the integrity of the joint.

Some Following concern of the Structure Consultant discusses below:

- Microstructural Changes: The high electric current used in the butt joint induces significant heat. That excess heat will change in microstructure and form undesirable properties.

- Tensile strength and Ductility: Heat-Affected Zone, is a region near the joint that has been altered by the heat generated during the butt joint. The HAZ can significantly impact the properties of the joint, particularly the tensile strength and ductility.

- Quality Control: To establish a strong joint, butt joint require control over variables including temperature, pressure, and alignment. To make sure that the execution process is meticulously controlled and confirmed. structural engineers should work closely with welders and quality control teams.

Is there any SOLUTION of HAZ?

Of course, Yes, The Cold Forging Process involves shaping the TMT bar after applying compressive pressure that can change the internal structure of the bar. Cold Forging of the bar enhances the Tensile Strength and Ductility of the Butt Joint.

Cold Forged Butt Joint:

Cold forged Butt Joint

During the forging process internal structure of the bar undergoes significant changes. The pressure applied during forging will cause the crystal structure of the bar to deform and realign because of that mechanical property will improve.

Cold Forging will improve several properties:

1. Strength

2. Durability

3. Ductility

Strength: Cold forging of the TMT bar increase the strength of the bar, making them more resistant to breaking and bending.

Durability: Cold forging of the TMT bar also improves the durability of the bar. it makes them better able to withstand harsh environmental conditions such as exposure to temperature fluctuation, moisture, etc.

Ductility: Cold forging of TMT bar improve the ductility of the bar, making them more flexible and resistant to cracking under stress.

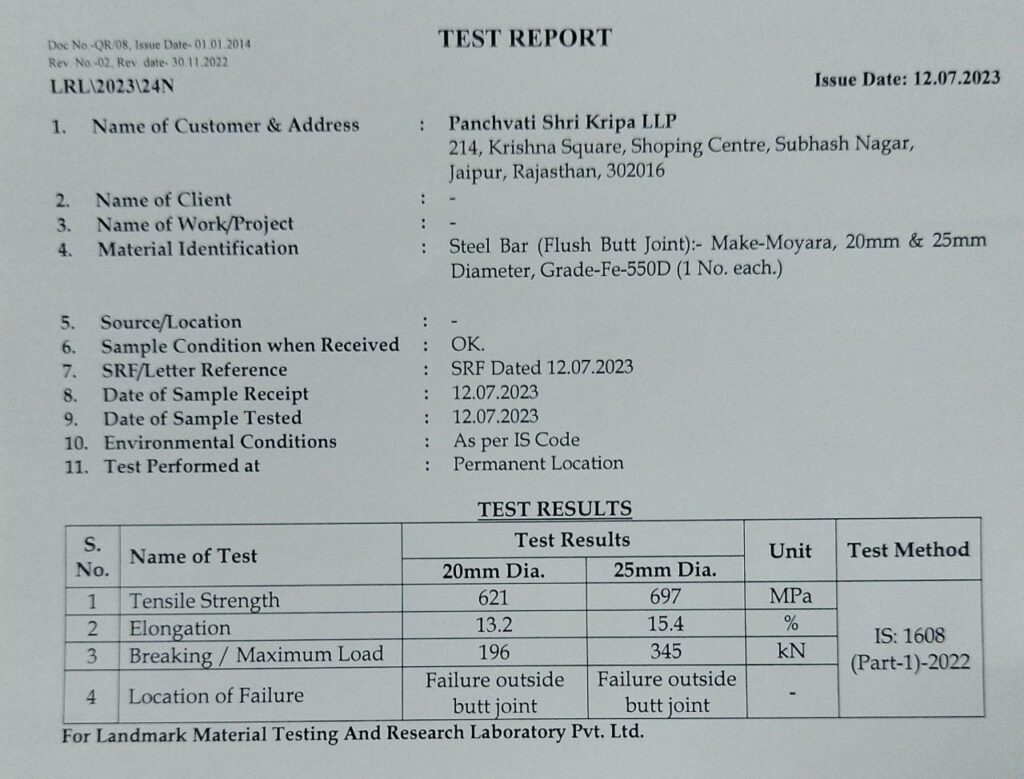

Landmark Test Report of Forged Butt Joint:

Conclusion:

When we join the TMT rebar without Cold Forging as per IS 9417:2018 the strength of the Butt joint achieved 90% of the ultimate tensile strength of the rebar because strength was reduced due to the Heat Affected Zone (HAZ). Therefore, we perform Cold forging on TMT rebar to increase tensile strength, which significantly reduces the impact of the HAZ in rebar during butt joint execution. As a result, the butt joint achieves 100% of its tensile strength, meaning it breaks at the self-bar when tested in a Universal Testing Machine (UTM).